Farmer's Market Logistics

Standard Operating Procedures for Sorting, Loading, and Transporting Product for Farmer's Markets

Table of Contents

Sorting Protocol

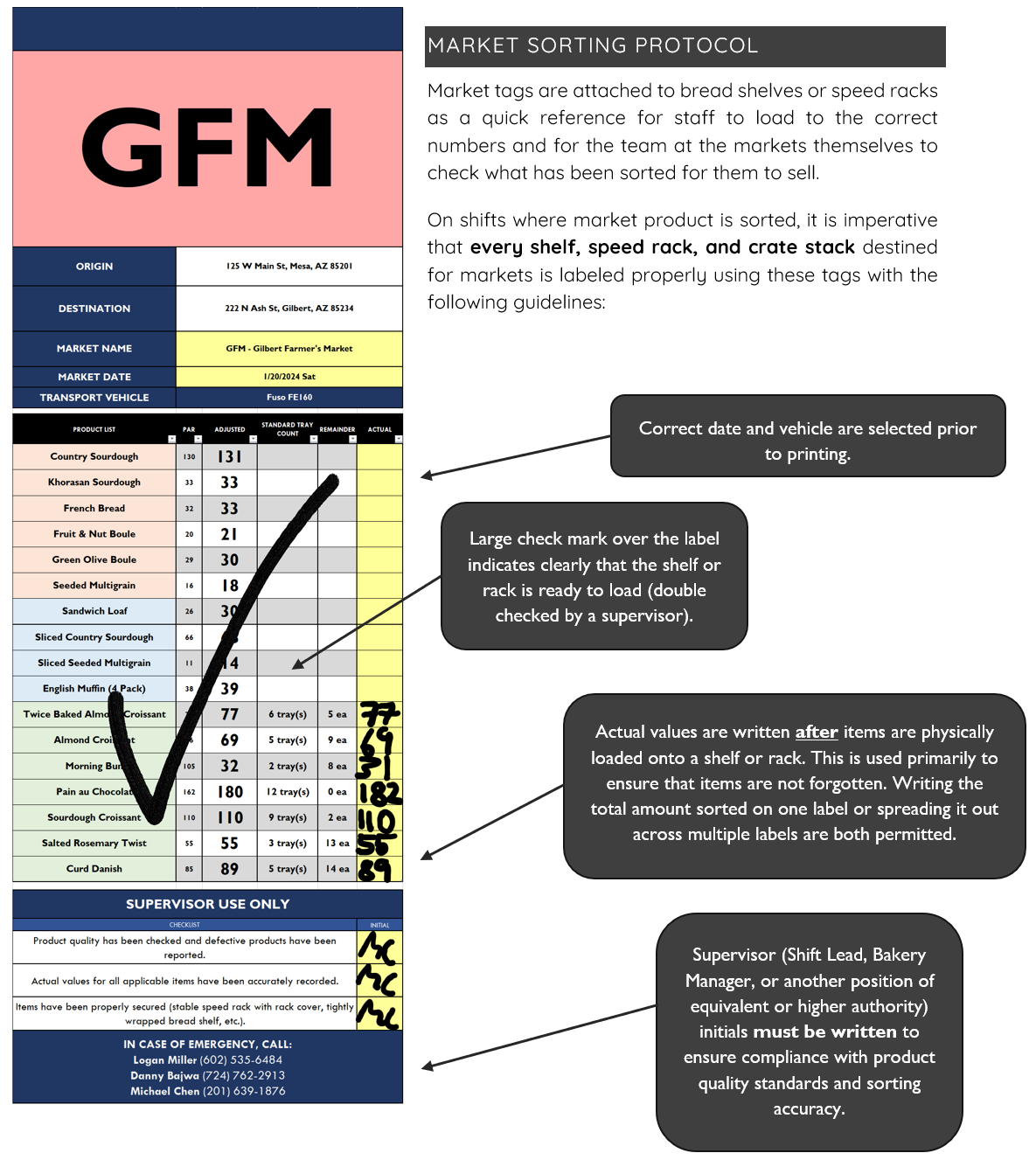

Market Tags

Key Guidelines

- Product Variety: Always be attentive that each market has received every type of product and matches the actual sorted values that are written down on market tags.

- Product Quality: Always take the time to report any defective products to a supervisor, who will then decide if a product is suitable for sale.

- Packaging for Transport: Ensure that all products are packaged securely and appropriately for transport and inspect equipment for structural integrity and stability.

Equipment-Specific Guidelines

Speed Racks

- Do not use speed racks that have loose or wobbly components, are in any way unstable, or are in any kind of condition that is unsuitable for the customer’s view. Report and tape off any racks that have any of these characteristics.

- Rack covers must be used for any speed racks with products on them.

- Rack covers that are excessively dirty or damaged must be disposed of.

- Ensure that all sides of the rack cover are properly zipped up and secure.

- Old tape labels must be removed from the racks or rack covers before use.

Bread Shelves

- Do not use shelves that have loose or severely damaged panels or casters, exposed ends of nails or screws, or are in any kind of condition that is unsuitable for the customer’s view. Report and tape off any shelves that have any of these characteristics.

- Stretch wrap must be used for bread shelves that contain any nonpackaged items.

- Stretch wrap suitable for wrapping pallets must be used. Foodservice wrap or any other method is not sufficient.

- Extra care should be taken to wrap the top of the shelf if the conditions are expected to be wet.

- Old tape or labels must be removed from the shelves before use.

- Old stretch wrap should be removed from the shelves before use.

Crates

- Do not stack crates to an unsafe height (greater than 6 ft, or more than 10 crates).

The crate stack must sit flat against the wheelbase. Ensure that no stacks sit at an angle. - The dollies used to transport the crate stack should always match the dimensions of the crates above. Do not use mismatched dollies.

- Crates with cracks or missing parts should not be used; they must be reported and disposed of.

- Failure to follow any of the above points will cause instability in the crate stack, putting valuable products and supplies at risk.

- The crates must be lined with parchment paper if nonpackaged product is placed in it.

- Old tape or labels must be removed from the crates before use.

Loading Protocol

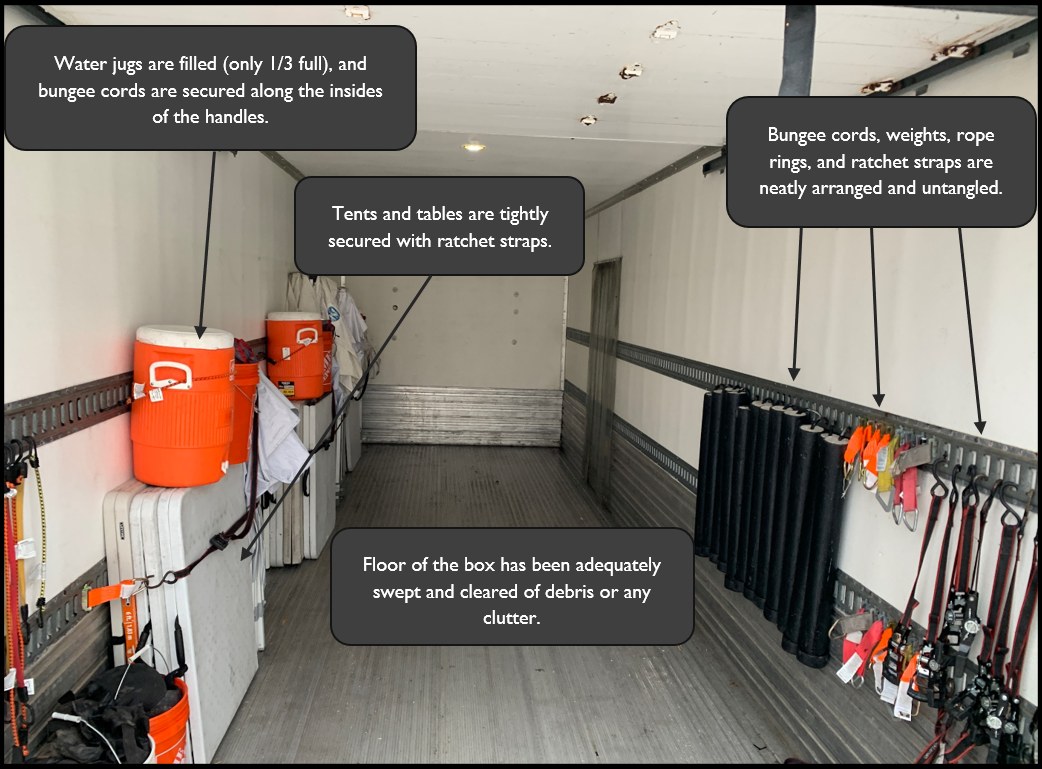

Truck Reset

Trucks used for markets should be returned to proper condition after the market returns on Saturday/Sunday, and before loading for markets again every Thursday. Follow the guidelines as outlined below:

Equipment Inventory

Vehicles should not have insufficient or excessive amounts of equipment onboard. This may change depending on the market or the specific needs of the week or the season.

Freightliner M2

- 3 Markets (typically)

- 2 Tents per market

- 3 Tables per market

- 6 Weights (concrete or sandbag) per market

- 1 Water Jug (1/3 full of clean water) per market

- 1 Empty Bucket per market

- 4 Tent Walls per market

- 8 Bungee Cords

- 8 Ratchet Straps

- 16 Rope Rings

Fuso FE160 / Isuzu NRR

- 2 Markets (typically)

- 2 Tents per market

- 3 Tables per market

- 6 Weights (concrete or sandbag) per market

- 1 Water Jug (1/3 full of clean water) per market

- 1 Empty Bucket per market

- 4 Tent Walls per market

- 6 Bungee Cords

- 6 Ratchet Straps

- 12 Rope Rings

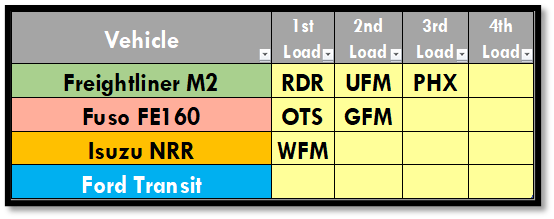

Load Order

- It is imperative that the load order of the vehicles corresponds with the predetermined route communicated to drivers (typically reverse of the drop order).

- Any changes to the load order must be communicated in the #logistics channel in Discord.

Lift Gate Operation

- It is strongly advised that at least two people are present when operating the lift gate to move products, supplies, or equipment.

- One person should operate the lift gate control.

- The other person should ensure that the item(s) on the lift gate remain secure and do not fall off.

- The person operating the lift gate control should ensure that the area in the pathway of the lift gate is clear and communicate clearly to their partner to ensure that they are ready for the lift gate to move up or down.

- Any personnel involved in the loading operation should keep their hands, feet, or any other part of their body clear of moving parts in the lift gate assembly or in the pathway of the lift gate.

- Proper lifting posture and technique should be used when lifting shelves, racks, or crate stacks onto the lift gate so as to avoid personal injury or damage to company property.

- Lift items from the bottom or the most stable part of the shelf, rack, or crate stack to get them over above door thresholds, cracks in the pavement, the lip of the lift gate, or crevices along the floor of the truck.

- Lift with knees bent, a straight back, feet flat, and hands secure on the object.

Work gloves are recommended to improve grip and prevent cuts or abrasions to the hands. - Extreme caution should be taken when operating the lift gate under wet or windy conditions. Extra measures should be taken to ensure the safety of personnel and company property.

- Do not operate the lift gate if it is damaged or unstable.

Ratchet Straps

- Do not roll too much webbing into the ratchet assembly. Pull the strap as tightly as possible first, then engage the ratchet.

- Do not pull the strap at an angle or cause the strap to fold while engaging the ratchet.

Improper use of ratchet straps as described above (see below) causes unnecessary wear to the ratchet and the strap webbing, fails to secure items properly, and takes a large amount of effort to undo. - Ratchet straps should be attached diagonally across to maximize stability of the strap against a bread shelf (see below).

- Avoid bracing ratchet straps against speed racks, and especially crates.

Loading Technique

- It is best practice to sandwich speed racks and crates between bread shelves, which will always have their front facing in, so a flat surface can be used to brace the ratchet strap against.

- Use rope rings if the slots on the side of the truck are insufficiently deep.

- Ensure that there is adequate space for each market’s respective equipment (tents, tables, etc.) to be easily accessible while unloading each market.

- Only the last item (usually a bread shelf) for each market should be secured by a ratchet strap. This way, each market is clearly separated by a ratchet strap.

Vehicle Parking Procedure

After ensuring that all markets have been loaded correctly into the vehicles, there should be care taken to ensure that the following procedures are followed:

- If the fuel or DEF (diesel exhaust fluid) gauge reads below 50% of a tank, it must be refilled before the next operation of the vehicle.

- If the vehicle is parked in a location where it is not expected to be, it must be reported to the #logistics channel in Discord.

- Headlights must be turned off.

- Box lights must be turned off.

- Cabin lights must be turned off.

- If the temperature outside exceeds 80°F, the refrigeration unit should be turned on and set to operate at 60°F.

- If the vehicle does not possess a refrigeration unit, the product should be held in the bakery or another suitable air-conditioned facility until shortly before departure.

- Vehicle cargo should be secured by a lock of adequate durability and pick resistance.

- Vehicle doors should be locked.

- Vehicle keys should be returned to their designated place.

Pre-Departure Protocol

Before departing on the market route, drivers should take the time to inspect the vehicle and cargo, as well as ensure that they are taking the correct vehicle on the correct route.

- Unlock and inspect the vehicle cargo bay to ensure that items are properly secured, and the cargo has been untampered with.

- Inspect vehicle tires for excessive wear.

- Inspect and test air brakes, if applicable.

- Check if any fluids are leaking from the bottom of the vehicle.

- Check for warning lights on the vehicle dashboard.

- If anything does not seem right, call your respective supervisor(s).

- Ensure that the vehicle has adequate fuel and/or DEF.

Routing

- Drivers should aim to drop off each market’s products and supplies at least one hour before the first schedule shift of market staff for each respective market.

- Several factors should be taken into consideration when planning out and scheduling the route:

- Geographical location of each market to optimize the route length and time.

- Differing opening times for each market

- Traffic present at certain areas along the route and certain hours of the day

- Expected weather patterns.

Unloading

- Drivers should be very aware of the specific characteristics of the areas around markets and the exact drop-off points within each market.

- Speed racks and crates should be sandwiched between bread shelves.\

- Brakes should be engaged on the bread shelves.

- Market equipment (tents, tables, water jug) should be neatly arranged and also sandwiched between bread shelves if possible.

- These assemblies should be wrapped with tent walls.

- In rainy or windy conditions, tents should be set up over these assemblies to keep products and supplies dry. Ensure that weights and bungee cords are used to keep it stable, depending on the severity of the conditions.

- Extra care should be taken to set up tent walls on the tents (see below) if necessary.

Upon finishing the unloading setup, drivers should take a picture of the drop and post it into the #logistics channel in Discord.

- When returning equipment and supplies to trucks on the return route, they should be reloaded the same way they were originally loaded (tents and walls should be secured with ratchet straps, etc.).